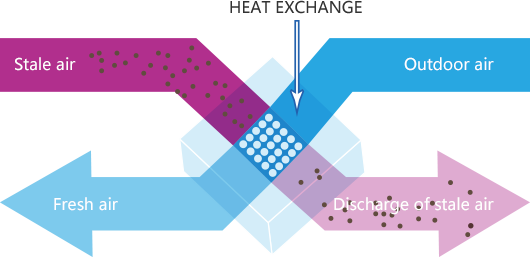

Outdoor and exhaust air separated by a thermal conductive plate to avoid cross contamination,Displacement ventilation, with incoming air pre-conditioned through heat exchange for energy conservation.

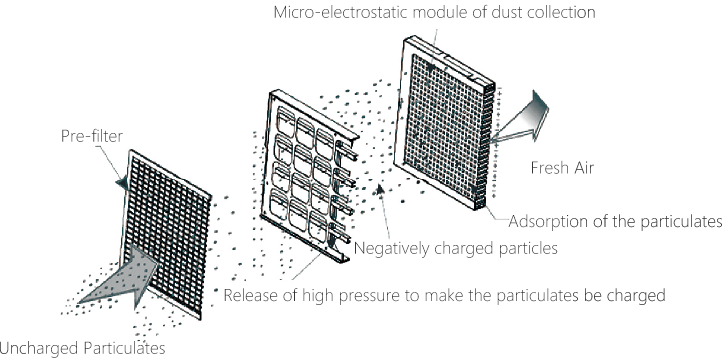

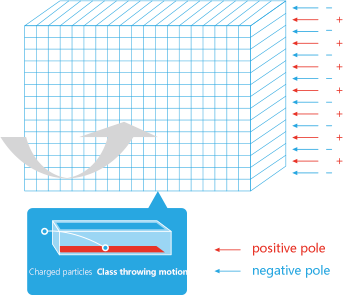

High voltage?(6KV-8KV) is applied to?generate corona discharges and negative ions. Negative irons collide with air molecules, thereby?ionizing?the latter and releasing additional irons which collide with further molecules—? creating an electron?avalanche.

When dispersed away from the corona discharge, negative ions are attracted by air molecules which become negatively charged and move towards the positive plate in an intense electric field.

Small particles are attracted to and obstruct the motion of negatively charged air molecules, hence acquiring negative charge.

Negatively charged particles are pulled to the positive plate and captured by the latter because of the powerful and polarized electrical field inside the ifD filter.

Real-time monitoring and remote control through a mobile APP

Selecting settings at the touch of a button

(Optional)

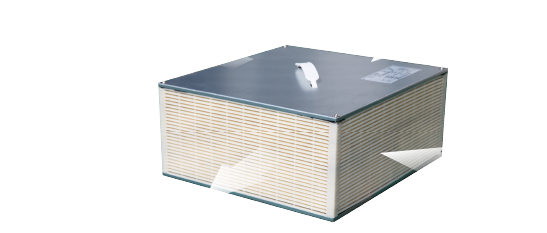

Outdoor and exhaust air separated by a thermal conductive plate to avoid cross contamination,Displacement ventilation, with incoming air pre-conditioned through heat exchange for energy conservation.

Fire-retardant and mold-resistant, the plate heat exchanger, consisting of semipermeable membranes, achieves optimal heat exchange efficiency by virtue of low friction and pressure losses and a large surface area.

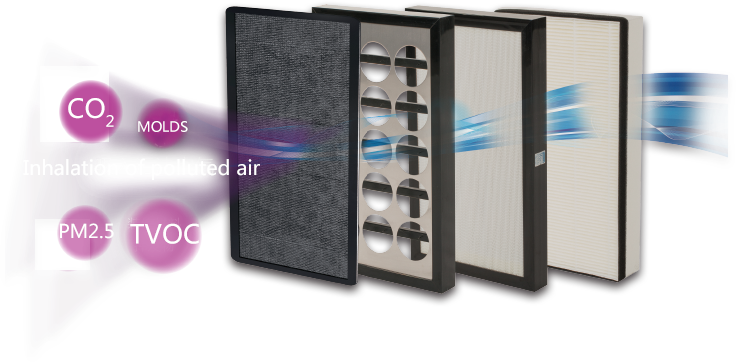

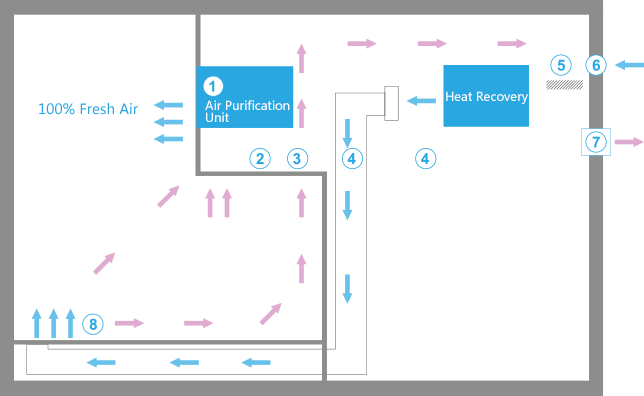

Air Purification Unit

Return air vent

Exhaust vent

Vertical shaft for air supply

Removal of PM 2.5 during the first purification process

Fresh air inlet

Discharge of exhaust air

Floor diffuser